After working as a volunteer for Smederij Atelier Alkmaar at the DKE (Dutch Knife Expo) i had some new inspiration.

The Expo was great, the workshops were busy and we had a real good day.

In this period a made some new things, tested different materials/shapes and mostly i had allot of fun.

I made a 'Brut de Forge' outdoor chef knife for a customer and my second axe.

The passion for Bushcraft and forging comes here together by making knives and axes:)

Take care Igor

.JPG) |

| After quencing i forgot to soften the blade and broke it with the stress test |

|

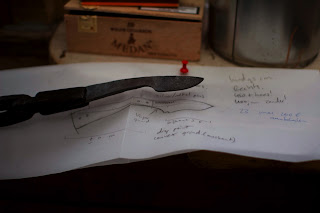

| Started this order for a chef, a outdoor kitchen knife, ModifiedCM60 steel. |

.JPG) |

| Finished product, with Desert Ironwood burl handle, silver/nickle pin and silver dutch coin. |

|

| The silver coin is a 2,5 dutch guilder from 1939. |

|

| 'Brut de Forge' mini bushcrafter |

|

| A 'Brute de Forge' mini Bushcrafter and a small Tomahawk/double side axe. | | |

|

|

| Made a Poplar handle and broke it after testing, so i made a new one from Beech. |

|

| It's my second forged axe and not the last one. |

.JPG) |

| I did not make these two viking axes, bought them on the DKE! |

|

| And made another Beech handle |

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)